MP3 Extrusion Growth partner of thermoformers in the world

MP3 is specialized in the extrusion of multi-layer sheets and reels for thermoforming.

Choose to grow with us by taking advantage of our cutting-edge technologies, our advanced skills in the physics of thermoplastic materials and industrial engineering and our vast experience in the extrusion of sheets and reels for thermoforming.

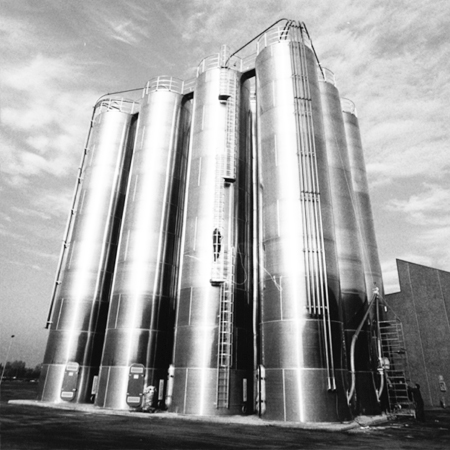

Production capacity

29tons of styrenic sheets

12tons of PS reels

13tons of PET reels

6tons of PP reels

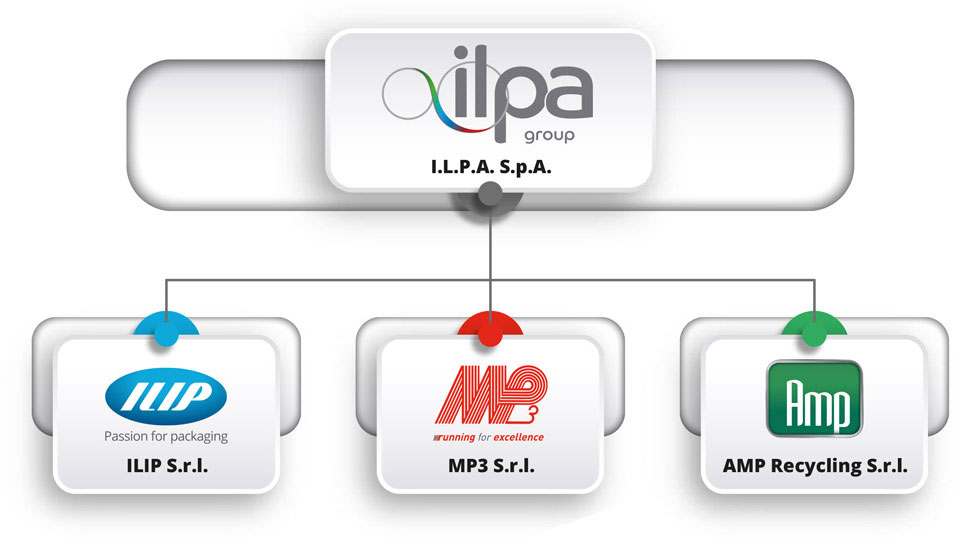

The companyThe group ILPA

The ILPA Group leads the European scene of thermoformed plastic and bioplastic food packaging production as well as the semi-finished plastic products market for use in the agricultural-food segment and all other industrial sectors.

In addition to MP3, other two companies belong to the Group: ILIP S.r.l., among the main European players in the Foodservice Packaging, Fresh Produce Packaging and Fresh Food Packaging sectors and AMP Recycling S.r.l., specialized in the recovery of post-consumer PET packaging and in the supply of guaranteed and certified flakes, granules and R-PET reels.

Today the ILPA Group serves over 4,000 B2B customers in more than 58 countries around the world.