The theme of sustainability is not new for MP3 and the ILPA Group, which have been carrying out projects and investments on several fronts for more than 15 years. The most important step is certainly the vertical integration achieved in 2012 with the acquisition of AMP Recycling, a company with a long tradition in the processing of plastics. This allows the Group to integrate the thermoforming and extrusion activities with a plastic material recycling plant dedicated to the recovery of PET from separated waste collection, guaranteeing a circular economy.

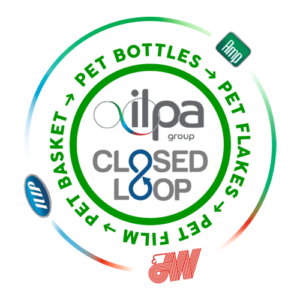

In fact, we recycle around 40,000t of post-consumer PET per year, which corresponds to the quantity of PET bottles consumed and recovered in the Emilia-Romagna region. We obtain secondary raw materials, avoiding the production of a corresponding quantity of virgin PET, which, in terms of CO2 emissions, corresponds to ca 75,000,000 kg of CO2 eq. These data are proven by the LCA (Life Cycle Assessment) studies carried out by the Group to measure the environmental impact related with the production of its products (specifically for packaging in PET/rPET or other polymers). These analysis and measurements consider the entire life of the product, including final disposal, and give an indication of the kg of CO2 emitted during its life cycle. For this reason, MP3 and the ILPA Group have dedicated gradually increasing efforts and resources to the assessment of the life cycle of products and semi-finished products, above all thanks to specific skills within the Research and Development department, who have been specially trained.

Since 2016, a decontamination plant has also been operating in the AMP Recycling plant, which has obtained the approval from EFSA (European Food Safety Authority) in the evaluation of our recycling process (EU Register N° RECYC105), allowing us to produce 100% rPET suitable for direct contact with food products.

In addition to the recycling policies and the reduction of the use of plastic materials (such as, for example, the fit4purpose packaging or the ILIP Life range), we are also committed to safeguarding non-renewable resources, investing in the use of more sustainable solutions. Bioplastics, for example, are valid alternatives to fossil polymers.

As for sheets, on the other hand, over the years we have increased our grinding capacity thanks to the 10 mills located in two separate departments, but also to the important investments in extrusion lines with state-of-the-art advanced filtration systems to ensure process stability and quality. With the introduction of the Premium project in 2018, i.e. the complete management of the various life stages of production waste, we are able to offer our quality by reducing the environmental impact of our products, while ensuring full traceability of materials and a processability equal to the virgin raw material.

Considering then the concept of sustainability in its broadest meaning, which includes not only environmental aspects but also economic and social ones, in MP3 as in the whole ILPA Group a “Code of Ethics” is in force, which defines, amongst other things, conduct in business, policies governing compliance with employment contracts, equal opportunities and behavior that is not permitted in the workplace. The areas range from environmental protection and the reduction of the environmental impact of its business and products during production, by controlling energy consumption, limiting CO2 emissions and fostering the development of procedures for the internal recovery of reject materials; to reducing occupational diseases and injuries with the growth and spread of a business culture aimed at preventing risks, incidents and emergencies, integrating health and safety management into all business processes.

In fact, the progetto ZERO is based on this last point, born in 2017 by factory workers with the aim of eliminating workplace accidents through the widespread involvement towards continuous improvement. This is also guaranteed through a dedicated team whose priority is the protection of occupational safety and the environment.