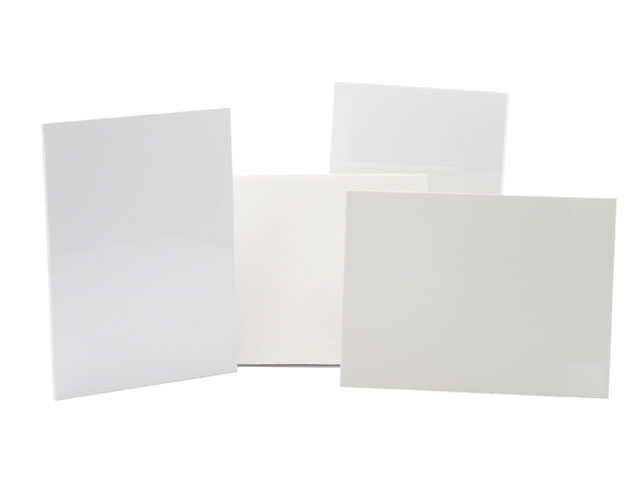

ProductsSheets

Our multilayer extrusion lines allow us to produce high quality plastic sheets for thermoforming. The philosophy of continuous improvement is applied to every production process, allowing us to reach the highest standards in the mechanical characteristics and finishes of our products. Every year we invest in new technologies and in upgrading of existing lines.

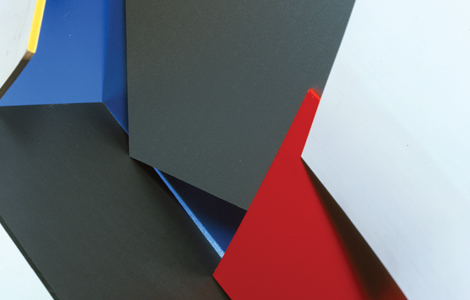

ACRYLAC QX 900

Co-extruded sheet of shockproof PMMA and ABS with excellent mechanical properties. High-end product for end applications requiring maximum impact resistance and good rigidity. PMMA gives excellent surface quality and UV protection. Mainly recommended for final products for external use.

Recommended applications

ACRYLAC PX 500

Co-extruded sheet of PMMA and ABS. The surface PMMA guarantees an excellent aesthetic quality to the final thermoformed. Our PX 500 is an excellent compromise between mechanical performance and aesthetics. Anyway, methacrylate (PMMA) guarantees good stability to UV rays. Primarily recommended for internal use end products.

Recommended applications

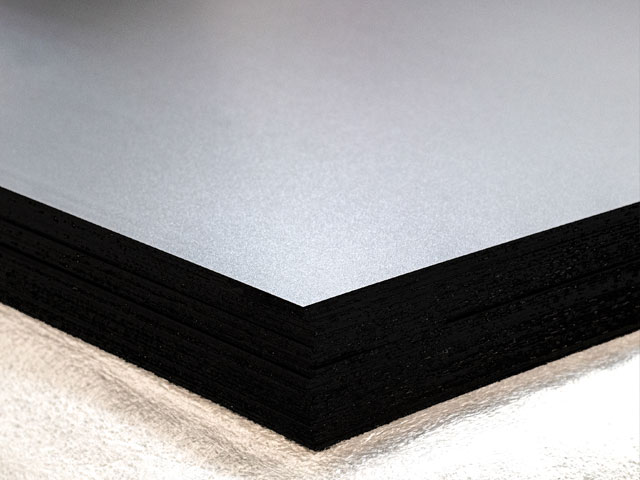

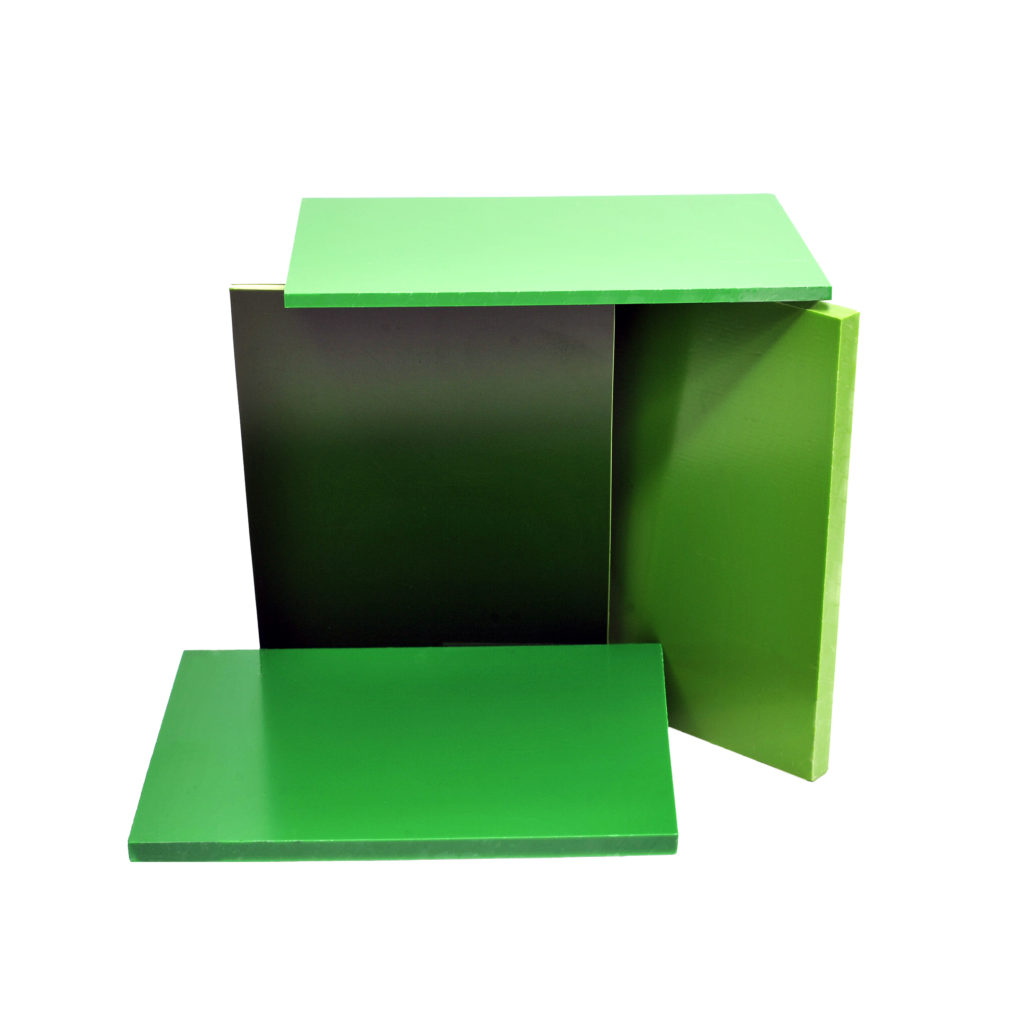

LAC 900

Obtained through an extrusion process of ABS (copolymer of STYRENE, BUTADIENE and ACRYLONITRILE). The grade of ABS chosen for this product is a mechanically superior grade that guarantees excellent impact resistance and excellent mechanical rigidity. Perfect for supporting mechanical stresses, impacts and stresses.

Recommended applications

LAC 700

LAC 700 is an ABS plastic sheet for thermoforming, ideal above all for all technical applications that require sturdiness.

Recommended applications

LAC 500

LAC 500 is a material for high-strength ABS thermoforming plastic sheets that can be customized in terms of color and characteristics.

Recommended applications

MP FR85

Co-extruded sheet of a special grade of HIGH IMPACT POLYSTYRENE which gives the sheet excellent chemical resistance performance. The excellent mechanical performance makes this product also suitable for use at low temperatures. Primarily recommended for industrial, domestic or RV refrigeration sectors.

Recommended applications

No match for current seletion, try to remove some filters.

there are no products for the current selection, try to remove a filter or remove all sections with the reset button