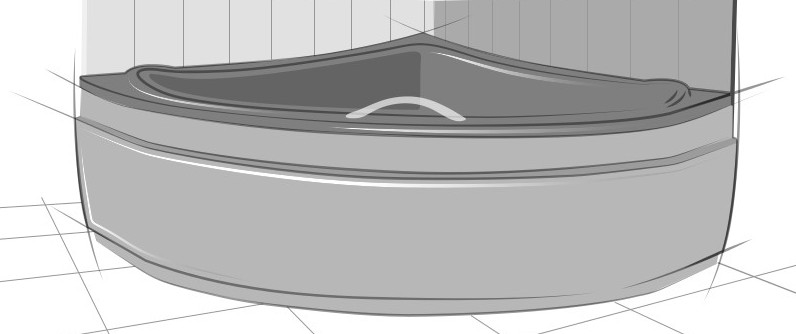

Panels

Our materials can be used also for the pannelling of shower boxes, bathtubs, saunas, etc.

Loading...

ACRYLAC PX 500

Co-extruded sheet of PMMA and ABS. The surface PMMA guarantees an excellent aesthetic quality to the final thermoformed. Our PX 500 is an excellent compromise between mechanical performance and aesthetics. Anyway, methacrylate (PMMA) guarantees good stability to UV rays. Primarily recommended for internal use end products.

Recommended applications

No match for current seletion, try to remove some filters.

there are no products for the current selection, try to remove a filter or remove all sections with the reset button