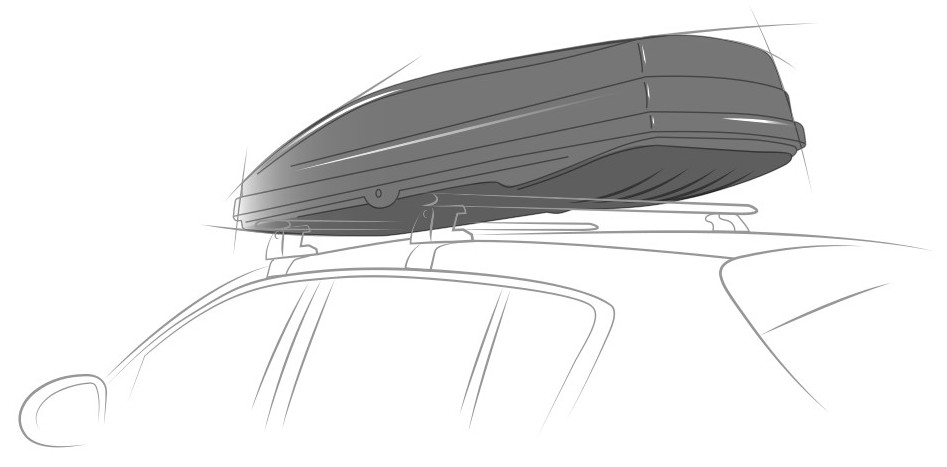

Car roof boxes

In this industry, our sheets are used mainly for the production of components for car luggage transport.

Because of the great variety of colours, finishes and treatments our materials particularly sought after by the leading manufacturers in this industry.

Our partners rely on our research and development to identify ever better materials that make the product more durable over time.

ACRYLAC PX 500

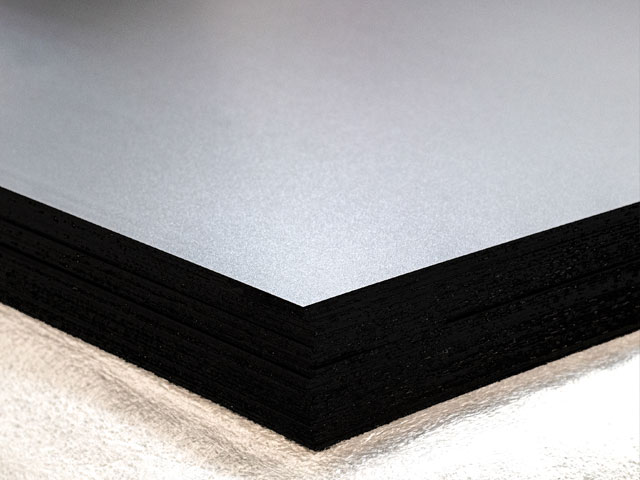

Co-extruded sheet of PMMA and ABS. The surface PMMA guarantees an excellent aesthetic quality to the final thermoformed. Our PX 500 is an excellent compromise between mechanical performance and aesthetics. Anyway, methacrylate (PMMA) guarantees good stability to UV rays. Primarily recommended for internal use end products.

Recommended applications

LAC 900

Obtained through an extrusion process of ABS (copolymer of STYRENE, BUTADIENE and ACRYLONITRILE). The grade of ABS chosen for this product is a mechanically superior grade that guarantees excellent impact resistance and excellent mechanical rigidity. Perfect for supporting mechanical stresses, impacts and stresses.

Recommended applications

LAC 700

LAC 700 is an ABS plastic sheet for thermoforming, ideal above all for all technical applications that require sturdiness.

Recommended applications

LAC 500

LAC 500 is a material for high-strength ABS thermoforming plastic sheets that can be customized in terms of color and characteristics.

Recommended applications

No match for current seletion, try to remove some filters.

there are no products for the current selection, try to remove a filter or remove all sections with the reset button